From Sketch to Showroom: Softwares that are used in designing a car

Published On 18/6/2024, 7:13:19 am Author Hritik BaberwalEver wondered how those sleek, futuristic cars go from dream to reality? The secret lies in a world of powerful software tools used by designers and engineers to bring their automotive visions to life. In this blog we will know about software that are used to design cars.

Car design software can be broadly categorized into two main areas: engineering and design.

Engineering software (CAE): These programs handle the technical aspects, focusing on things like performance, safety, and functionality. They allow engineers to simulate various scenarios, such as crash tests and aerodynamic flow, to ensure the car meets all safety regulations and performs optimally. Examples of CAE software include ANSYS and Abaqus.

Mechanical Design software (CAD): This is where the artistic magic happens! Design software allows stylists to create stunning visuals, experiment with different shapes and features, and ultimately sculpt the car's aesthetic identity. Popular CAD programs include Dassault Systèmes' CATIA and Siemens NX.

Then Comes Styling software (CAS) and rendering software: These softwares include Autodesk Alias and Keyshot.

From Sketch to Sculpture: The Design Pipeline

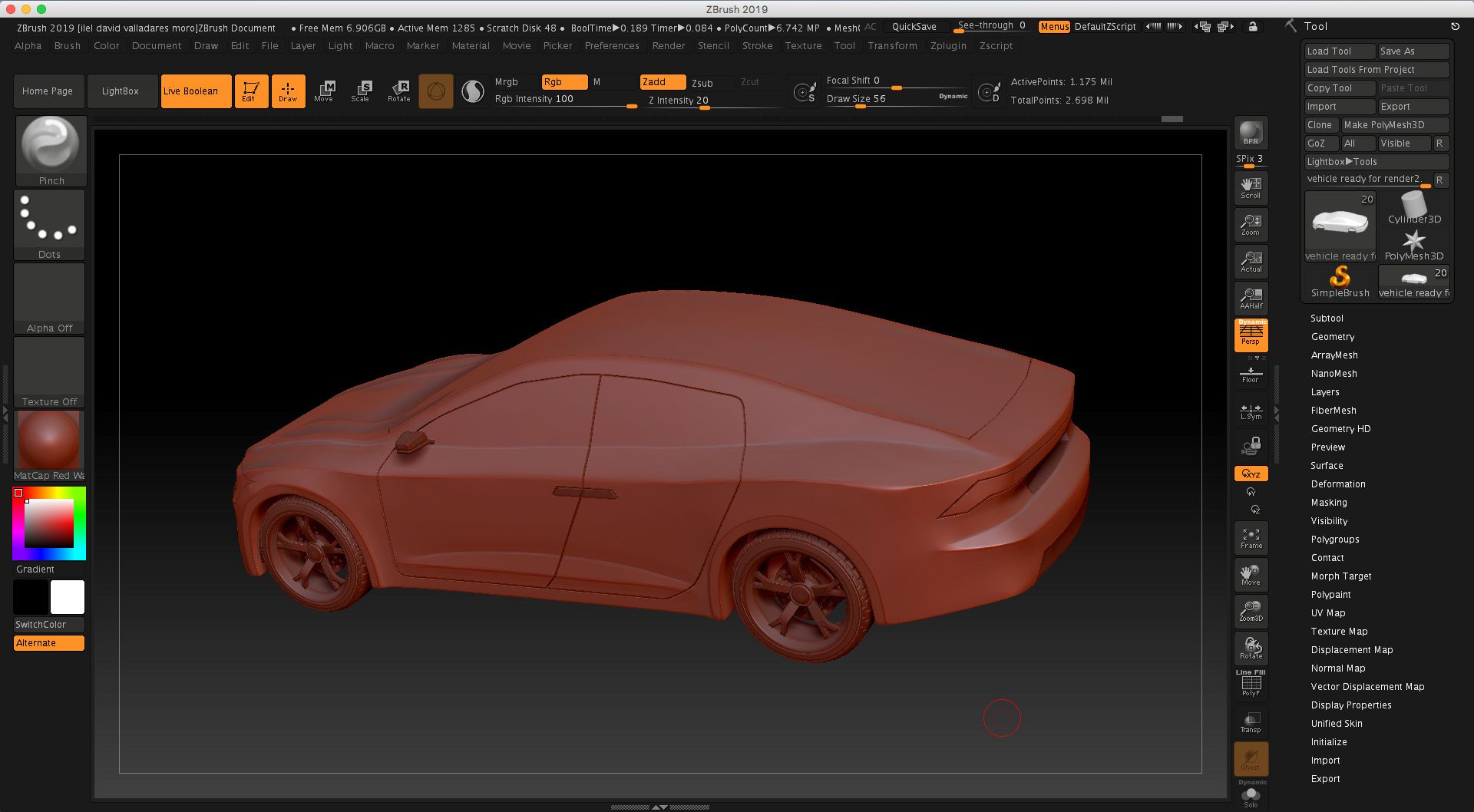

The design process starts with a sketch – a rough drawing capturing the initial vision. Here's where the magic of digital sculpting software comes in. Programs like Autodesk Mudbox or ZBrush allow designers to refine the sketch digitally, creating a 3D model with realistic proportions and details. This digital model serves as the blueprint for the next stage: the clay model.

The clay model is a physical representation of the digital model, sculpted by hand. This allows designers to further refine the car's form and identify any potential issues that might not be apparent on screen. Once the clay model is finalized, it goes through a process called digital scanning.

The clay model is a physical representation of the digital model, sculpted by hand. This allows designers to further refine the car's form and identify any potential issues that might not be apparent on screen. Once the clay model is finalized, it goes through a process called digital scanning.

The scanned model is then imported into software like Autodesk Alias, a powerhouse for automotive surfacing. Alias allows designers to create the car's smooth, continuous surfaces with incredible precision. This stage is crucial for ensuring the car not only looks stunning but also functions properly from a manufacturing standpoint.

The scanned model is then imported into software like Autodesk Alias, a powerhouse for automotive surfacing. Alias allows designers to create the car's smooth, continuous surfaces with incredible precision. This stage is crucial for ensuring the car not only looks stunning but also functions properly from a manufacturing standpoint.

The story doesn't end there! Once the design is finalized, other specialized software comes into play. CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) programs like Siemens NX or PTC Creo seamlessly bridge the gap between design and production, allowing engineers to generate instructions for building the car on the factory floor. Additionally, Computational Fluid Dynamics (CFD) software like ANSYS Fluent helps optimize the car's aerodynamics, minimizing drag and improving fuel efficiency.